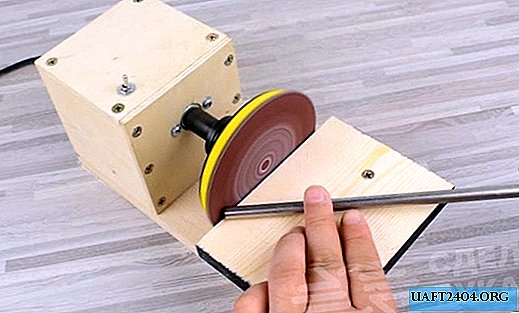

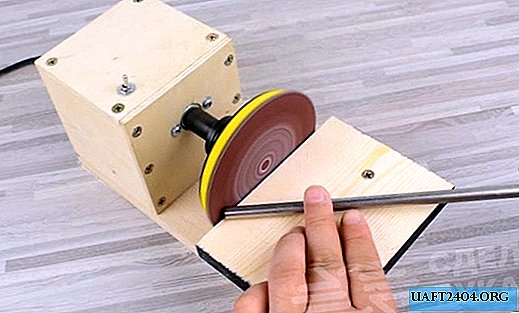

For grinding small wooden or metal parts at home, it is not at all necessary to purchase a large grinding machine, which, in addition to taking up a lot of space, also works quite noisily. Therefore, it is possible to make a more compact and quiet grinding machine with a drive from the 775th electric motor.

The main stages of work

For this homemade product you will need a 775 motor, which can be inexpensively bought on Aliexpress, an M10 adapter for a grinding wheel (put on the motor shaft), a grinding wheel with a shank and a switch.

To make the case and the stand, it will be necessary to cut planks of wood or plywood in the following sizes:

- 240x95 mm and 130x95 mm (13 mm thick);

- 95x90 mm (5 mm thick);

- 90x90 mm (13 mm thick) - 2 pieces;

- 95x95 mm (5 mm thick);

- 55x37 mm (13 mm thick) - 2 pieces.

In wooden blanks we mark and drill holes for self-tapping screws, and then proceed to assembly: a housing for an electric motor is mounted on the base, as well as a work table for more convenient grinding of parts.

An M10 adapter is put on the motor shaft, onto which a grinding disk with Velcro is screwed to fix abrasive wheels. In the upper part of the wooden casing for the motor, a toggle switch or on / off button is installed. Lastly, you need to connect the wires and fix the plug connector for the power supply to 12-24V and 5A.