To make a home-made oscillating-spindle grinding machine, you need a drive, which is perfect for a motor from a 420 W washing machine, a steel pipe with an inner diameter of 50 mm, a power supply unit for 12V and 10A, bearings with an inner diameter of 20 mm (outer - 47 mm), as well as bearings 8x22 mm.

Of the additional materials, the following will be required:

- electric motor from wipers (wipers);

- fasteners - bolts with M8 nuts;

- shock absorber strut shaft from a passenger car.

The main stages of work

From a water pipe with an inner diameter of 50 mm, it is necessary to cut a piece 9-10 cm long, which must be cut along the grinder. Then we put two bearings on the shaft, insert it into the pipe, which we clamp in a vice, and scald.

Next, we weld a shaft with bearings to the electric motor pulley. It is necessary to weld two pieces of a square profile pipe 15x15 mm to a steel pipe. Then, we make from guides of a corner and a profile of a rectangular section, we make 2 guides, which are interconnected by means of a jumper.

At the next stage, we insert the electric motor together with the shaft and bearings into the resulting U-shaped frame, and then fix it rigidly by welding. Then it will be necessary to make two more guides from the corners, on which then four bearings must be installed.

Machine assembly

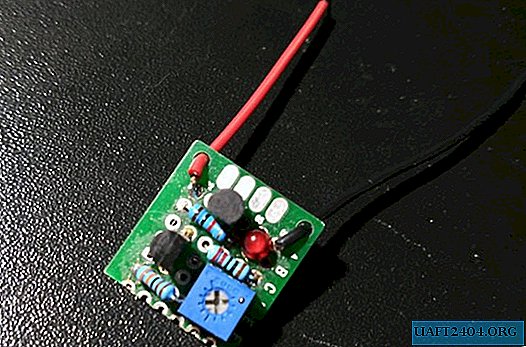

Then we weld a rectangular frame from profile pipes 15x15 mm or 20x20 mm, in the middle of which (in the upper and lower parts) the guides are welded, after which the electric motor itself is installed. Next, we attach a rigid spring to both frames and install the motor from the wipers and the power supply.

At the last stage, we make a swivel and collect all the structural elements. We cover the frame with plywood, and also make a countertop with a central hole for removing chips. See the video on the site for the assembly process of the oscillation-spindle grinding machine.