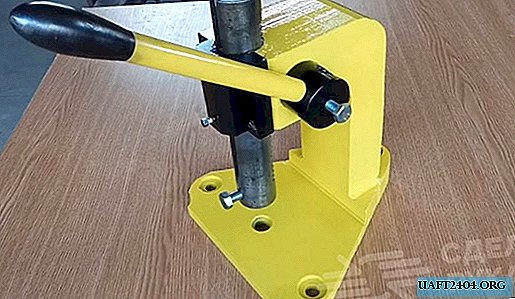

Sometimes grinding machines are urgently needed, but there is no suitable engine at hand to make a good unit. However, this is not a reason for frustration. As an electric drive, you can use a conventional household drill. It is only necessary to make a base, as well as a table for grinding workpieces with the possibility of height adjustment.

As a base, a piece of metal 10 mm thick with dimensions 28x33 cm is suitable. In principle, you can use a sheet of other sizes (at your discretion). A metal plate 6 mm thick and 80 mm wide will also be required. Vertical racks can be made from a profile pipe 50x50 mm.

Of the purchased components for the manufacture of a grinding machine, you will need a Velcro disk for emery wheels, as well as a special mount for the drill. However, if desired, fastening with a clamp under the "neck" of the electric drill body can be made independently.

The main stages of work

At the edges of a 28x33 cm metal plate, we drill through holes for installing legs with rubber tips so that the machine does not “run” along the surface of the table during operation. Then we cut off a piece of a plate 80 mm wide and a piece of a profile 50x50 mm. We weld them together.

In this case, the plate will act as an element to which the fastening for the drill will be screwed. We weld it to the base of the machine. Also, at a certain distance, it is necessary to weld the second piece of the profile 50x50 mm.

At the last stage of work, we weld a small piece of a plate with a width of 80 mm to a profile pipe 40x40 mm. It will be a table for supporting workpieces. Details on how to make a compact grinding machine with a drive from a drill with your own hands can be found in the video on the website.