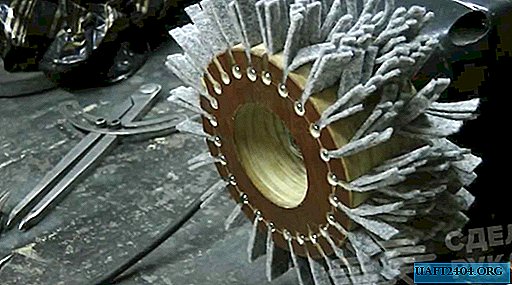

For convenient and high-quality polishing of various metal parts having a concave or convex shape, as well as even workpieces, you can use a home-made felt polishing drum.

The master himself makes the drum from bakelite plywood, which, of course, is more expensive than ordinary plywood, but differs in better strength characteristics. The master himself decided to make polishing cassettes from felt.

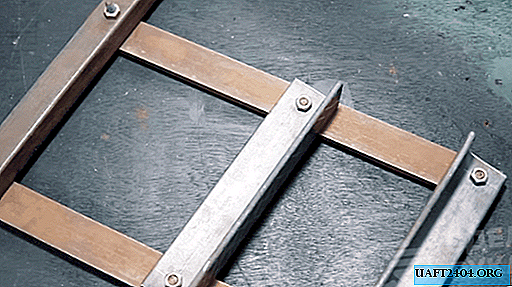

First you need to cut out two billets of round shape from bakelite plywood, which the master glues together to get the drum of the required thickness.

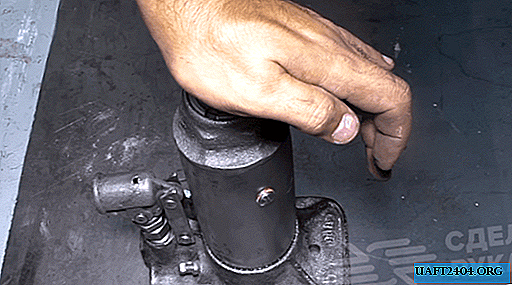

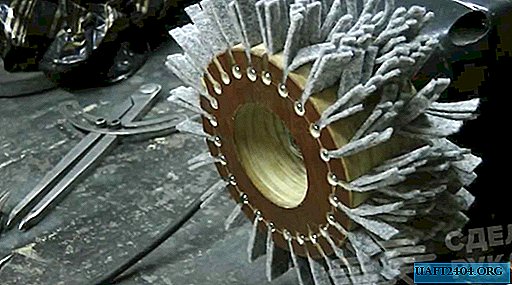

After gluing, the drum needs to be turned on a lathe. Also, in the center it will be necessary to make a recess, and drill a hole for the diameter of the shaft of the emery machine electric motor. All these operations are performed on a lathe.

Polishing drum manufacturing process

At the next stage, on a drilling machine or using an electric drill, it is necessary to drill holes around the entire circumference.

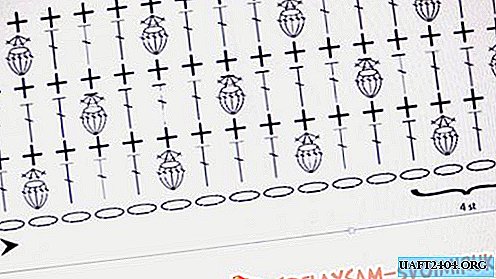

Then grooves for polishing cartridges are cut. And for their fixation, the master cuts pieces of a steel bar of a suitable diameter. You can use, for example, damp or old electrodes, beating them from the coating.

Next, the master cuts the strips of felt of the desired width, and then cuts them into pieces of the desired size. It is better to cut the material with sewing scissors, ordinary ones can not cope. Then they are installed in the slots in the drum and fixed with pieces of steel bar.

The main advantage of this drum is not only ease of manufacture, but also versatility. Instead of felt polishing cassettes, any material can be used: hard tarpaulin, sandpaper, soft wool, etc.