In this review, the author shows how you can make a small profile bend yourself from different trash.

With the help of this device (mini machine), it is possible to bend profile pipes of different sections with an arc, and even make rings out of them.

As the base, a piece of the channel is used. You will also need to make shafts from the jet traction "Lada" and bearings.

The main stages of work

First of all, the author marks out a piece of the channel and cuts it with a grinder, but not completely. Then it will be necessary to weld the awnings. And only after that we finish the channel with the grinder to the end. We weld seams and edges in the place of the cut with a petal disk.

At the next stage, we weld profile sections to the channel - these will be “seats” for shafts with bearings.

Further, from the pieces of the corner, the author makes two racks for a profile bending machine with an opening for the central shaft.

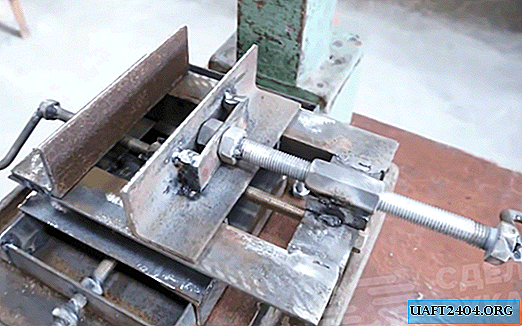

After that, the author proceeds to manufacture the lower base of the profile bending machine. This will require a thick metal plate and pieces of profile.

Profile bending assembly

Further, it will be necessary to weld together the lower and upper part of the profile bending machine.

To the lower base, the author welds a car jack. To the inner side of the channel you need to weld a piece of the stud, which will go into the groove on the jack.

At the last stage, we fasten two racks from the corner to the bolts. Then it remains only to make a pen and paint the finished product.

For details on how to make your own profile bending machine for your home workshop and garage, see the video on the site.