Share

Pin

Tweet

Send

Share

Send

During welding, there are times when it is necessary to simultaneously grab the part and hold it at a certain angle. For such work, two people or a special tool is needed. The most commonly used clamp. With its help, fix the part set in the right position. However, the clamp has a bunch of disadvantages. Therefore, you need a special magnetic holder that will help to perform this work quickly and without unnecessary trouble.

Advantages of a magnetic corner for welding

- Able to hold both metal parts, which frees up your hands to do the main job.

- Does not block access to the junction, which makes it better than a clamp.

- Allows you to create several options for angles.

- Easy to use.

- It does not require large expenses in manufacturing.

The process of manufacturing a magnetic corner

First, we need a magnetic disk with a diameter of ~ 15 cm and an inner diameter of ~ 5 cm. It is also necessary to have squares of sheet metal with a thickness of 3 mm, with a side of 20 cm. It is very important that the sides of the square are perfectly even. It is desirable that the magnet in thickness does not exceed the material most used in the work. The best option is 1-1.5 cm.

We place the magnet in the center of the square and circle it with a marker to create a markup. Next, we apply the cut lines on the metal, which must be done to create a pattern.

We clamp the workpiece in a vice, and with the help of the turbine we cut off the excess elements.

We apply the resulting part to the second square to circle its contours. Next, we also remove the excess from it with a turbine.

We connect the two obtained workpieces together and grab it by welding. Now we can perform one operation, immediately on two parts.

Next, we need two threaded couplings. We install a magnet on the workpiece, applying it to the previously designated place. Then we distribute the coupling around its perimeter, at the same distance from each other. We mark their position with a marker.

We remove the couplings. We mark the holes in the center of the location of the couplings. Next, using a drill corresponding to the diameter of the hole in the coupling, we make holes in our workpiece. It is through them that bolts for fixing will be installed.

After that, we weld a piece of pipe to the workpiece, with the diameter of the magnet’s inner hole. We fix it in this place. As a result, we got a part that can be clamped in the chuck of a lathe.

Using a drill and a cutter on the machine, we create a hole equal to the inner diameter of the magnetic ring.

We remove the welded pipe and clean our part. At the same time, it is very important to get perfectly even edges, keeping the corners in line. Therefore, you will have to work not only with a grinding machine, but also with a file. We make a kind of measuring tool, which means that the accuracy of the work must be at its best.

In the next step, we will need couplings and bolts for them.

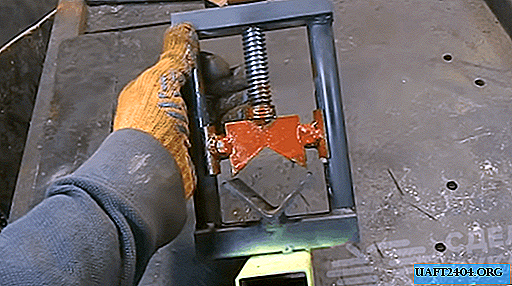

The workpieces are disconnected and cleaned. Next, a magnet and couplings are mounted on one of them.

From above, they are covered with a second blank, fixing the location with bolts through the couplings, but not tightening them to the end.

At the final stage, the structure is aligned and checked for compliance with the corners. Only then tighten the bolts. The magnetic template is ready to go.

Share

Pin

Tweet

Send

Share

Send