Share

Pin

Tweet

Send

Share

Send

When threading in duralumin or aluminum, failure can occur and your tap will break, leaving a chip inside the hole. Drilling tool steel from duralumin-aluminum is incredibly difficult and this means that the entire hole will be broken. There is a way in which the hole in the workpiece remains intact, and the chip can be removed without much difficulty.

The method is based on the difference of electrode potentials in different metals. In this regard, the contact of aluminum (its alloys) with steel (iron) results in galvanic vapor. If you immerse such a pair in acid, then galvanic corrosion of steel will immediately begin.

By the size of a similar tap, you can estimate how deep the chip lies.

Mark with a marker for clarity.

Everything is clearly visible under the microscope.

Will be required for etching

- A pack of citric acid in powder 100 gr.

- Water from the tap 150-200 ml.

- Utensils for etching. I will use stainless steel, but an ordinary enameled pan is fine.

Pour 2-3 teaspoons of citric acid into a cup and fill with water.

The electrolyte is ready.

Citric Acid Etcher

We put the cup with the solution on the fire and lower the part with the broken-off tap into it.

Bring to a boil and reduce to a minimum fire, but so that inactive boiling of the liquid continues.

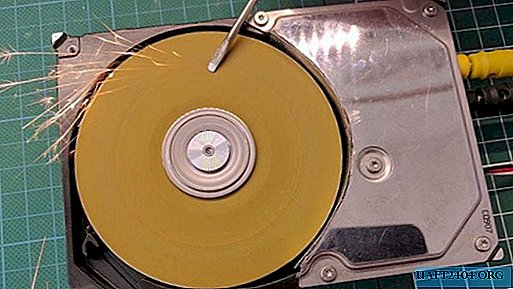

After 30 minutes.

After two hours of active etching.

We add water and acid, as the water boils away, and the acid goes into the reaction.

After several hours, you can observe a black coating on the bottom of the dishes - the result of a chemical reaction.

Three hours passed and the tap had already burned noticeably.

After five hours of etching, nothing is visible in the groove.

I managed to extract the tap chip itself with taps.

The minutes were recorded on the leaflet, after which the condition was checked, plus water was added and citric acid was added.

With a similar tap, you can see what happened to the chip after a chemical reaction.

Here is such a simple, but rather long-lasting method. It is good when the part is small and fits perfectly in a saucepan. Harder when the part is massive.

See the video for a complete and detailed process.

Share

Pin

Tweet

Send

Share

Send