Share

Pin

Tweet

Send

Share

Send

Start with bevel strips

The main elements of this universal system are horizontal slats:

- Supporting, having a 45 ° bevel on the upper edge and fixed on the wall.

- Suspended with a bevel on the lower edge, fixed on a removable panel or cabinet.

Plan the location of the wall planks based on your needs. You can organize several levels of tool storage from floor to ceiling or use the space above the workbench by installing two or three support bars. Having decided on the total length of the rails, prepare a smooth lumber with a section of 30x150 mm. Fasten the boards to the workbench and set the circular saw blade at a 45 ° angle.

Adjust the longitudinal stop to a size of 60 mm to get different rails. Wider support strips will go to the walls, since they must withstand a large load. For suspensions of the individual components, narrower boards are enough.

Cut and sand the workpieces, apply the finish and install the wall parts at the desired height. Align the boards horizontally and make sure they are in the same plane. Use linings if necessary.

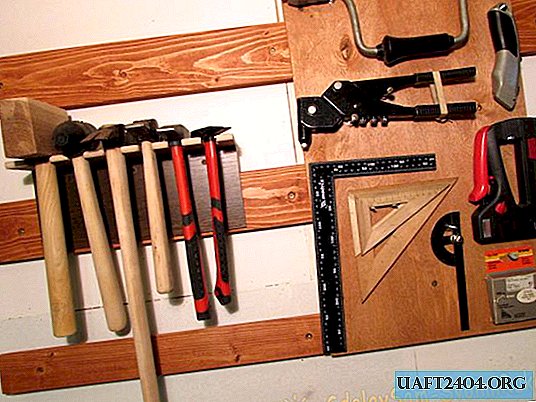

For storage of instruments of various shapes, panels are better suited, and for the same type of equipment it is recommended to use holder racks. Let us further consider examples of the manufacture of such devices with their own hands.

Make a hanging panel

Lay out your tools on the table, leaving a gap between them. Take the dimensions of the future panel, taking into account the distance between the wall planks.

Cut a rectangle of 5 mm plywood with a hacksaw and cut planks with bevels along its width.

Assemble the hinged shield by fastening the parts with screws through the countersink guide holes.

Mark up to store tools that can be hung on a pin.

Drill through the mounting holes and recess on the back side where the protruding nuts interfere with the suspension.

Insert the studs with nuts into the holes and tighten the threaded connection.

As pins, you can also use bolts, the caps of which will additionally hold the tool.

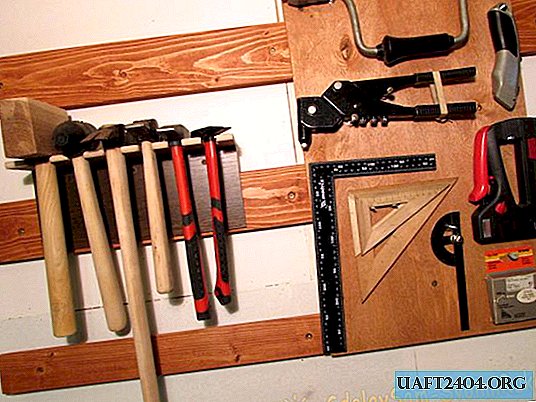

Having placed everything you need on the panel, hang it in place.

Add hammer pendant

A homemade device for storing hammers consists of three parts: a holder, a block with a bevel and a back.

First, determine the dimensions of the holder, depending on the dimensions of your hammers.

Saw a piece of appropriate length and width from 12 mm birch plywood.

Mark the grooves on it and make through holes with a feather drill with a diameter of the width of the cut.

Saw straight lines and remove excess material. Sand the edges of the grooves with sandpaper screwed onto the tube.

Saw the length of the hanging bar and grind off the upper edge with a planer at an angle of 2 °.

Screw the holder to the rail with countersunk screws, having previously prepared the mounting holes with countersink.

Saw the backdrop from a dense sheet material with a thickness of 5-10 mm, fix it on the bar with small screws.

Place the fixture on the suspension in a convenient place and fill it with hammers.

A similar holder design is also suitable for storing tube or rack clamps, you only need to calculate the dimensions of the cutouts and the gaps of the holder bar.

Consider a convenient and affordable arrangement of tools and fixtures. Store specialized accessories near workplaces where they are used. For example, planers are at the workbench, and next to the assembly table are clamps and screwdrivers. Inexpensive marking tools (rulers, pencils, squares, etc.) are useful to have in excess and store in different places so that they are always at hand.

Share

Pin

Tweet

Send

Share

Send